The research projects TRANSLATE and NXTGENWOOD, which are funded by the EU and Irish Government (DAFM) respectively, aim to develop new nanofluidic platform technologies to effectively convert waste heat to electricity. The work conducted by the Materials Chemistry and Analysis Group (MCAG) is key to the success of these projects.

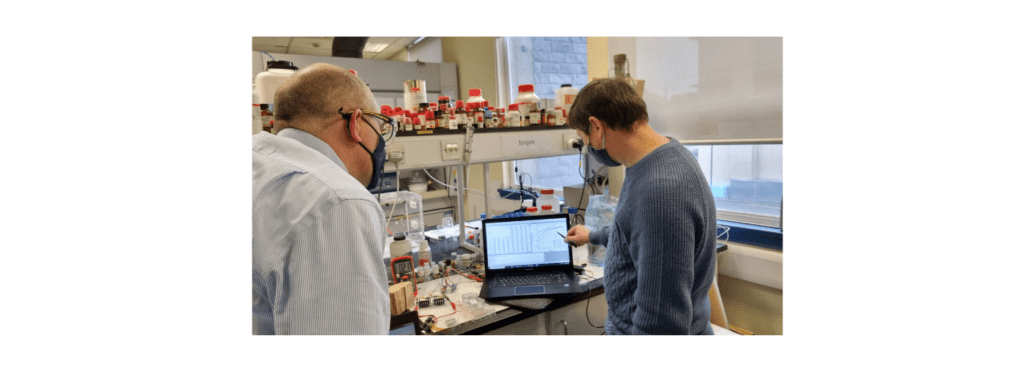

Recently we had the opportunity to visit our partners, the Materials Chemistry and Analysis Group (MCAG) from UCC in their lab.

Project coordinator Professor Justin Holmes, and team members Dr Ievgen Nedrygailov and Dr Scott Monaghan, gave us a taste of what they are currently working on for the TRANSLATE project. Their team have been looking at the properties of several natural materials, which could be used in our thermoelectric device to conduct electricity as a sustainable alternative to materials used in other existing thermoelectric devices. For our visit, we looked at cellulose – a cheap, environmentally friendly, and completely renewable material that can be obtained from the waste of the wood industry.

Ievgen showed us a simple chemical process for making cellulose from eucalyptus wood using chemicals available in the kitchen of any household. The idea is that cellulose fibers are naturally occurring nanostructures with unique ionic conduction properties. When these fibers are filled with an electrolyte containing high concentrations of ions (such as sodium and chloride ions produced when table salt is dissolved in water), cellulose becomes a thermoelectric material and can convert heat into electricity.

The process starts with a piece of Eucalyptus bark.

The bark is simmered for approximately one week in an oxidising solution (such as hydrogen peroxide).

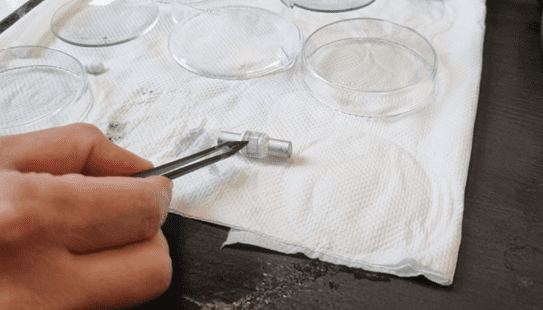

This process removes lignin and hemicellulose from the bark, leaving cellulose fibers forming a system of channels with a diameter of only a few tens of nanometers. The bark must be simmered at a low temperature to keep the cellulose channels intact. These nanochannels are critical to the operation of our final prototype.

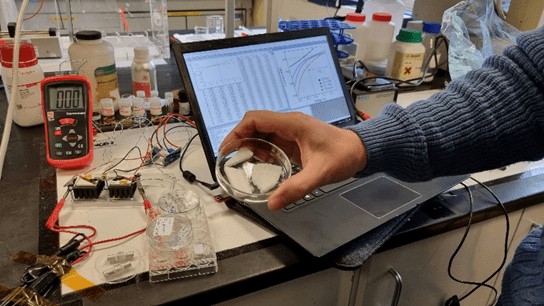

The dried cellulose is placed in a vacuumed cell, filled with salt water (our electrolyte).

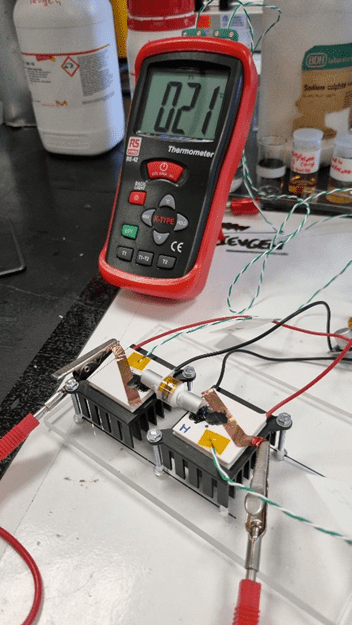

A prototype thermoelectric module is installed on a test platform that can generate a temperature gradient due to the operation of two Peltier elements. One of these elements serves as a cooler, the other as a heater. The platform also contains a thermocouple for measuring the temperature difference between the cold and hot ends of the thermoelectric module. A potentiometer is connected to the prototype to measure current, thermopower, and other characteristics.

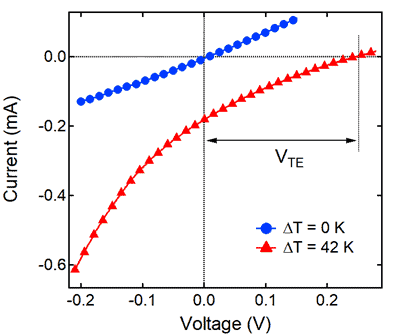

When different temperatures are applied to either side of the platform, we generate a voltage and current that could have many useful applications, such as powering a small electronic device. We also see that the power of the electric current we generate is higher when the amount of thermal energy supplied to the module increases.

This is the behaviour we expected and hoped for, based on a theory from our project partners at Technische Universität Darmstadt, and it is the first proof of concept for our proposed device in the lab! TRANSLATE Work Package 1 leader, Professor Steffen Hardt recently wrote an article on our website explaining the physics of thermoelectric energy conversion in nanochannels which is worth a read.

If we apply this concept to our device, we can generate electricity from waste heat!

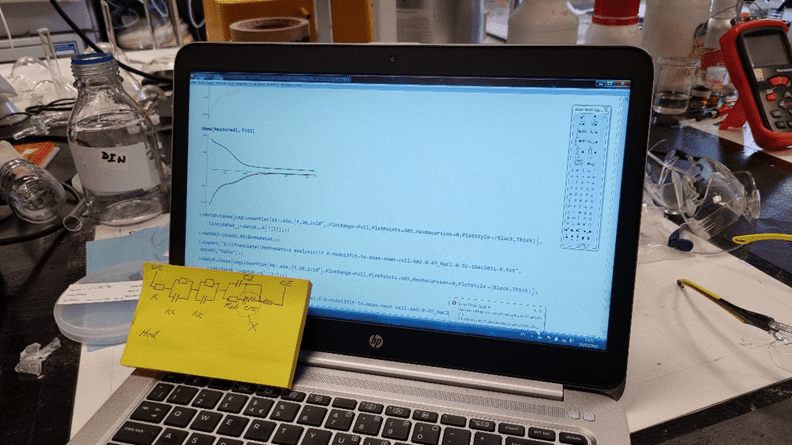

To help us further understand our experiments, Scott has built a model of the circuit using Mathematica. The material, electrolyte, and structure of the cell all relate to a circuit component like a resistor, capacitor, or inductor, and by slowly building up the complexity of the model and matching it to experimental data, we can start to fully understand the system and what elements are responsible for creating the increased voltage.

The next step for the MCAG team will be to study the impedance of materials under a series of frequencies, to further understand the circuit and how it responds to a salt solution. The team are also exploring more synthetic materials such as aluminium oxide.

This work will help the TRANSLATE team to select optimal materials for our prototype device to generate electricity from waste heat.

We can’t wait to visit the MCAG team again very soon to see further developments!