How do we turn wasted heat – from our devices, homes, and even our bodies – into usable electricity? That’s exactly what PhD researcher Anjali Ashokan has been working on as part of the TRANSLATE project. Her recent publication, Ion-Selective Transport in Surface-Modified Cellulose Membranes for Aqueous Ionic Thermoelectrics, demonstrates how sustainable cellulose membranes can be engineered to significantly enhance ionic thermoelectric performance.

We sat down with Anjali to learn more about her research journey, the breakthroughs behind this work, and what it could mean for the future of sustainable energy.

What inspired you to explore surface charge engineering in cellulose membranes for ionic thermoelectrics?

I was motivated by a simple problem: salty water on its own doesn’t generate much voltage from a temperature difference, so it’s hard to turn low-temperature “waste” heat into valuable electricity. The idea was that if we gave a soft, sponge-like membrane a controlled electric charge, we could guide ion movement and dramatically boost the effect. Cellulose was a natural platform for this because it’s renewable, already widely used in filters, and its surface charge can be tuned using straightforward, water-based chemistry.

You worked with two types of functional groups: TEMPO and CHMAC. Why those?

I chose TEMPO and CHMAC because they let us “dial in” opposite charges on the same cellulose platform using simple, water-based chemistry. TEMPO turns some of the cellulose into negatively charged sites, while CHMAC adds permanent positive charges. Together, they provide a clear side-by-side comparison of how negative vs. positive surface charge affects how ions move and how much thermal voltage we can generate from a temperature difference.

And the results were striking – a tenfold increase in the Seebeck coefficient and a 950-fold increase in conductivity. How did CHMAC membranes achieve this?

CHMAC gives the cellulose membrane a strong, permanent positive charge, so it starts acting like a tiny ion “filter.” It pulls in and channels negatively charged ions much more efficiently than in plain salty water. At low salt levels, this surface effect dominates, so instead of ions wandering randomly, they flow in a highly directed way through the charged pores. That’s what leads to both the ~tenfold jump in voltage per degree and the huge boost in conductivity.

What challenges did you face?

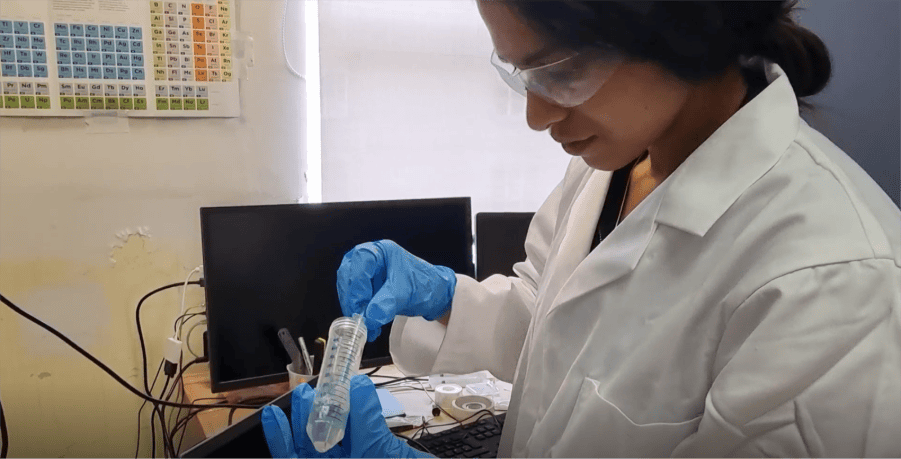

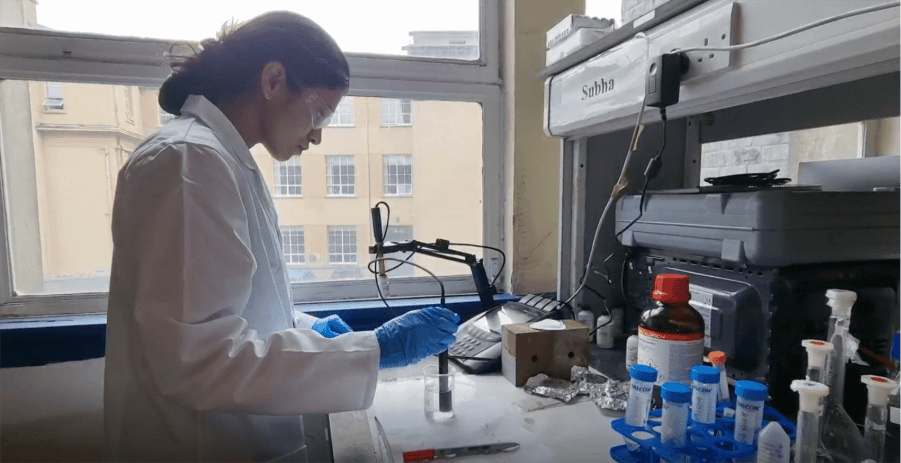

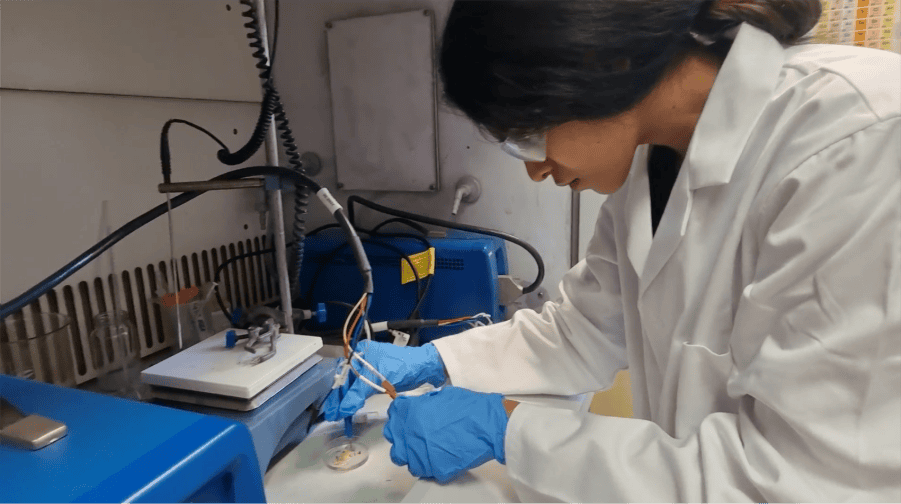

One big challenge was measuring the effect we were interested in. We had to build a custom setup that could hold flexible, wet membranes, apply a tiny temperature difference, and still reliably detect tiny voltages and currents without interference. On top of that, we had to tweak the surface chemistry, so we added charge without damaging the cellulose structure — there was a lot of trial and error and rebuilding along the way.

Sounds like it. How scalable is this surface modification process? Could industry adopt it?

It’s still early-stage research, so we’re thinking more about small-scale applications than giant factory lines. The chemistry is water-based and straightforward, and we start from commercial cellulose filter membranes, so making more of these modified membranes in modest batches is very realistic. The most likely first targets are small-area devices – such as sensors, test strips, or patch-style modules – that only require centimetres of material. Still, you need it to be reliable and reproducible.

Where do you see this technology being applied?

In the near term, I see this technology in small, low-power devices rather than anything large-scale – think skin-worn patches, smart bandages, or environmental sensors that quietly harvest a bit of energy from temperature differences. Because the membranes are soft, water-processed, and made from cellulose, they’re well-suited to gentle contact with people, liquids, or delicate surfaces. Longer term, the same ideas could help power distributed sensors in buildings or on equipment by tapping into the low-grade heat we usually ignore.

What’s next for your research?

We’re now testing other kinds of cellulose membranes, from lab-made nanofibrillated films to thicker sheets, and exploring new ways to add charge, such as silane chemistry. All of this will feed into my PhD, where I’ll compare how different membrane types and surface tweaks perform side by side.

Finally, how has being part of TRANSLATE shaped your journey?

TRANSLATE has been incredible for collaboration. I’ve had the chance to work with colleagues across Europe – from Germany, Latvia, Ireland and beyond. The feedback and ideas from so many perspectives have shaped my work and helped me grow as a researcher. It’s been a great platform for both exposure and learning.

Takeaway

The takeaway is that a very familiar, sustainable material, cellulose, can be tuned to give a surprisingly strong electrical response from small temperature differences, simply by changing its surface charge. We’re not talking about powering phones or cars, but about creating tiny “trickle power” sources for things like sensors, skin patches, or smart labels that need only tiny amounts of energy. My work shows that with clever surface chemistry, cellulose membranes can deliver much higher thermal voltages and ion flow than before, making them a promising building block for the next generation of soft, low-power devices.

You may also like to read “Harvesting Electricity from Wood: The NXTGENWOOD-TRANSLATE Link“

Read the full publication here: Ion-Selective Transport in Surface-Modified Cellulose Membranes for Aqueous Ionic Thermoelectrics